360 Degree Automatic Optical Inspection and Sorting Machine for Fasteners

Types: RK-1500 Glass Plate Optical Sorting Machine

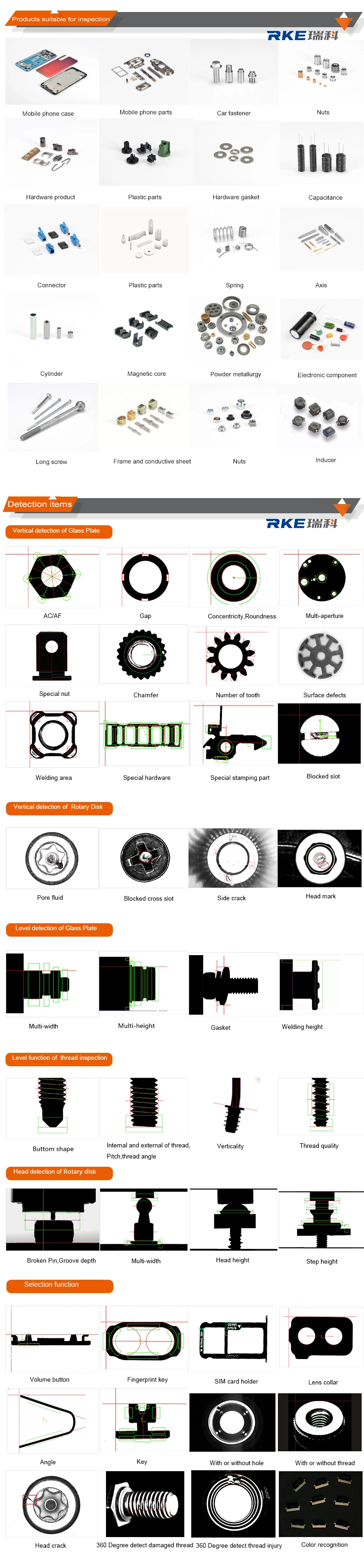

Suited for: Screws, nuts,micro screws, plastic and rubber parts, electronic component etc.

Inspected products

Inspecting screen

The inspection screen comes equipped with three industrial cameras.

Camera 1 is Horizontal camera , inspect the multi-height and outer diameter .

Camera 2 is Vertical bottom view camera , inspect head cross slot or flat slot.

Additional 1 to 4 sets of cameras can be added for inspecting thread damage or other defects of the product with a complete 360 degree view.

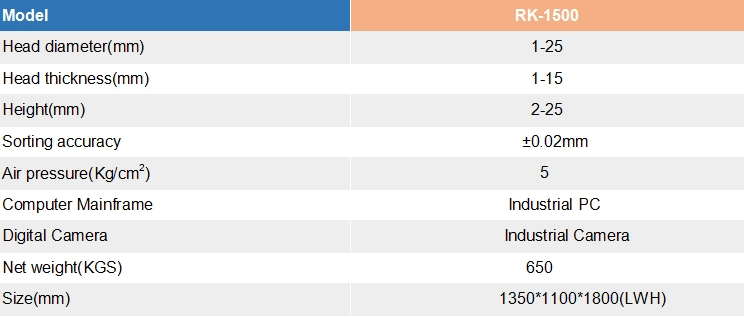

Technology parameters:

Note: Customized service can be provided according to the detect demand.

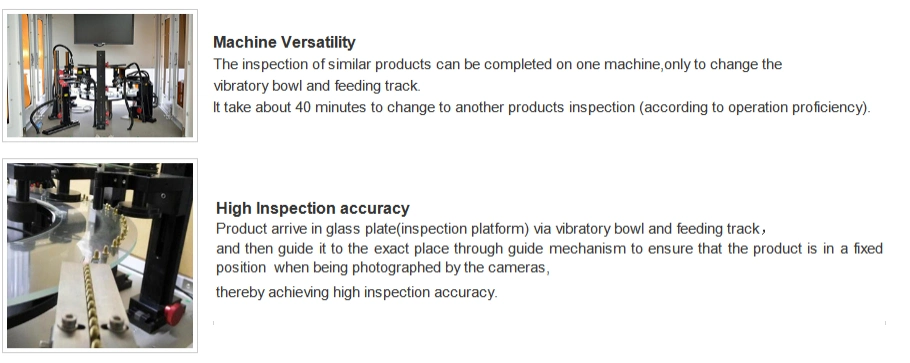

Machine Features:

1.Highly-transparent glass plate.

2.Fit for grease-free parts which can be placed on the glass plate securely.

3.Wide detection range of fasteners,mobile phone parts,rubber products,electronic components ,special-shaped hardware,screw etc.

4.Detection camera:can 2-6 cameras can added according to the inspect items.

5.Detection speed:300~1000 PCS /min Depend on individual case.

6.Automatic counting packaging machine and automatic feeding system can be added according to customer demand.

Available Inspection Items:

| Diameter,Hole diameter | Roundness |

| Length | With coating |

| Width | With mark |

| Height,Thickness | With cut/tapering |

| Surface defect | Parallel edge length |

| Deformed,Broken | Broken pin,Recess depth |

| Different shape | With thread |

| Crack | Fine or coarse thread |

| Burrs,Chips | Tooth numbers |

| Across Corners | Pitch |

| Across Flat | Slanted thread |

| Chamfer angle | Minor diameter |

| Included angle | Major diameter |

| Arc radius | Hardness |

| Concentricity | Recognition of different materials |

| With or without heat treatment |

Delivery and Package:

Shipping

1.Upon receipt of payment,delivery date will be in 25-30 working days.

2.By Sea,by Air or by Express(DHL etc.)

Packing in plywood cases (No Fumigation required ) ,or packed according to customer's requirement.

Service Advantage:

1, Warranty: 12 months FREE overseas service.

2, Enjoy lifelong maintenance.

3, Professional service team, to provide 24 hours, 365 days of technical support.

4.Offer remote online service ,if there is no solution within 2 hours,door to door service will be offered after both parties negotiation.

5.Convenient service ,response for your machine breakdown in the shortest time and get rid of your worry.

Welcome to ask for details.

If you could provide related samples and test items, a project plan will be send to you after practical test by us. Then discuss the equipment specification and procurement plan.

We promise that most suitable machine with costing the least money.